A car stacker hoist, or a car lift or parking lift, is a mechanical parking device used to store vehicles in a compact space vertically. This system is particularly useful in areas with limited parking space, such as urban environments, residential garages, and commercial parking lots. So, This document provides an overview of car stacker hoists, including their types, operation, benefits, installation, maintenance considerations, etc.

Specifications:

- Place of Origin: Shandong, China

- Product name: Car stacker Parking

- Brand: Tada

- Warranty: 1 year

- Load Capacity: 2000kg-3000kg

- Dimensions of cars: 5300mmx1900mmx1900mm

- Certification: CE MEA ISO

- Power Supply: 3 phase 5 line

- Operation Voltage: 24V

- Surface Treatment: Spray painting or hot-dip galvanizing

Types of Parking Systems

Car stacker hoists come in various types, each designed to meet specific needs and space constraints. Therefore, the main types include:

Quad Stacker Parking System: This device divides parking spaces into four layers by vertically lifting them to store more vehicles. This type of equipment achieves the goal of stacking 4 cars on the ground space of the same parking space through mechanical devices such as lifting.

Triple Stacker Parking System: This type of equipment achieves the goal of stacking 3 cars on the ground space of the same parking space through mechanical devices such as lifting.

Double Stacker System: The device lifts a vehicle onto a platform and locks the platform in place so that the driver can park a second vehicle in the space below the platform.

Furthermore, Car stacker hoists use different mechanisms to lift and lower vehicles, but the most common methods include:

Hydraulic Operation: Uses hydraulic fluid and pistons to raise and lower the platform.

Electric Operation: Uses electric motors to drive the lifting mechanism.

Safety Features:

Safety Locks: Prevent the platform from descending unexpectedly.

Sensors: Detect the presence of objects and prevent collisions.

Emergency Stop Buttons: Allow the operator to immediately stop the lift in case of an emergency.

How does it work:

Vehicle storage process: After the vehicle enters the lowest parking space, the driver and passengers leave the vehicle and start the equipment through the control system. At this point, the lower loading plate rises to leave space for the middle-level vehicles, which are then raised to the top level as well. In this way, each layer can store a car in sequence.

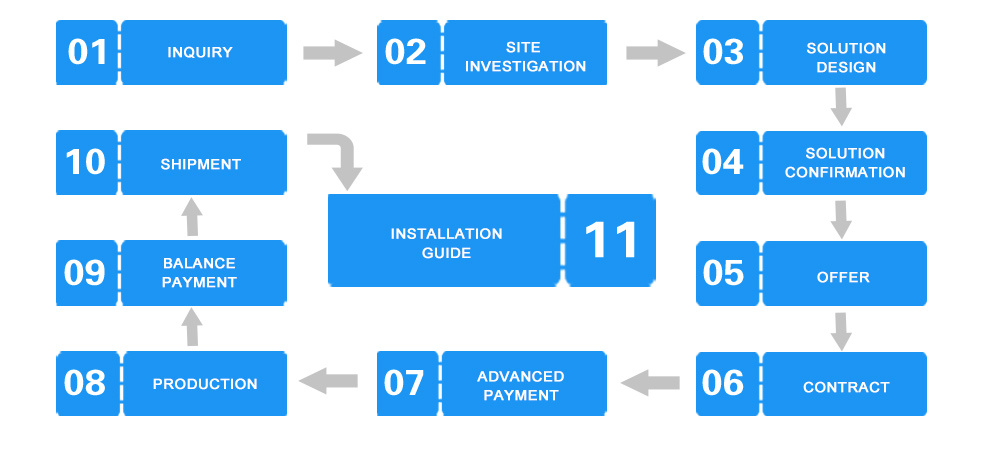

Purchase Guide: